How should the fully automatic head-hanging folding mask machine be protected and inspected?

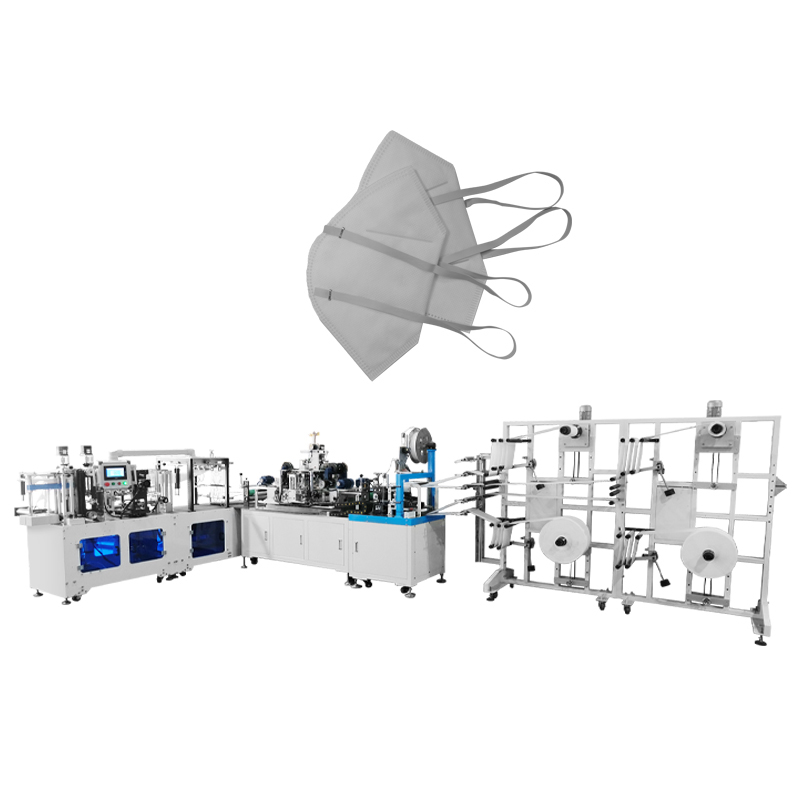

The fully automatic head-hanging folding mask machine, also known as the C-type mask machine, is a machine that fully automatically produces folding mask bodies. The machine uses ultrasonic technology to bond 3 to 5 layers of PP non-woven fabrics, activated carbon, and filter materials, and then cuts them out. The foldable mask body can process 3M 9001, 9002 and other mask bodies. Depending on the raw materials used, the masks produced can meet different standards such as FFP1, FFP2, N95, etc. The ear straps are made of elastic non-woven fabric, and the filter cloth layer of the mask is It has good filtration effect and can be used in high-pollution industries such as construction and mining.

What are the functions and characteristics of the fully automatic head-hanging folding mask machine? Let's take a look.

1. The main body of folding masks such as 3M 9001 and 9002 can be processed in one step. 2. PLC automatic control, automatic counting. 3. The adjustment device is simple and refueling is convenient. 4. Using swappable molds, molds can be quickly replaced to produce different types of masks.

Any equipment is inseparable from maintenance. Reasonable maintenance can effectively improve the working efficiency and service life of the equipment. It can also detect some minor faults in time to avoid larger problems causing economic losses. Then the fully automatic head-hanging folding mask machine should How to protect and inspect it? Let's take a look.

1. Air supply system: It consists of air filter system, air pipe and cylinder. Check whether there is water in the air filter cup and drain it to the air compressor (air compressor drainage: in areas with high humidity, it should be drained to the air compressor every day) , check whether the air pipe is leaking, whether the cylinder is leaking, the direction of the cylinder's magnetic sensor and whether the operation is normal.

2. Ultrasonic system: It consists of an ultrasonic electric box, vibrator, welding head, and connecting wire. Check whether the ultrasonic system is clean. In particular, the ultrasonic electric box, vibrator (transducer), and welding head (expansion ratio) need to be cleaned monotonically. There should be no water, the connection line needs to be firm, and the wear degree of the ultrasonic welding joint should be checked frequently. Pay attention to the changing patterns of the voltmeter and ammeter pointers on the ultrasonic electric box.

3. Electrical system: Check whether the circuit connectors of the equipment are loose, whether the main power cord and branch signal wires are worn or aged, whether the electrical appliances are loose, whether the inside of the electrical box is clean and drab, and whether the exhaust fan is working properly.

The fully automatic head-hanging folding mask machine equipment has many characteristics such as fast production speed, short process flow, high output, and good quality. What are the precautions when using the fully-automatic head-hanging folding mask machine equipment? Let's take a look.

1. The pressure of each component should be appropriately adjusted to reduce the load on the entire machine.

2. When the machine is started, all raw materials must be manually pulled into the welding mold before the equipment can produce normally.

3. All bearings should be inspected regularly to ensure normal operation during operation.

4. Before turning on the machine, the ultrasonic welding machine should be turned on first to avoid excessive load and burning out the ultrasonic welding machine.

-

What are the debugging methods of flat mask machine?Apr,15,2024

What are the debugging methods of flat mask machine?Apr,15,2024 -

Market application of fully automatic N95 mask machineJun,11,2024

Market application of fully automatic N95 mask machineJun,11,2024 -

Mask equipment manufacturing solutions: an innovative force leading the development of the industryMar,29,2024

Mask equipment manufacturing solutions: an innovative force leading the development of the industryMar,29,2024 -

How to reduce the failure rate of mask machines?May,17,2024

How to reduce the failure rate of mask machines?May,17,2024 -

Fully automatic high-speed folding mask machine manufacturer briefly analyzes the things to pay attention to when choosing a mask machineApr,01,2024

Fully automatic high-speed folding mask machine manufacturer briefly analyzes the things to pay attention to when choosing a mask machineApr,01,2024

Links

Links